Plating

Our rectifiers have been widely applied for chromezincnickelcooper,etc. metal surface plating, and for PCB plating, precious metal plating, automotive parts, and some other higher requirements hardware surface treatment

For widely applied metal surface plating, our IGBT switch rectifier provides precise output, reliable, compact structure, efficient energy-saving solution. Air cooling and water-cooled version are available.

Thyristor rectifier(silicon controlled rectifier) is a very robust and endurable solution. Air cooling, water-cooled, water-oil cooling, and oil cooling could be provided.

Customization is as requested on your specific crafts requirement.

For PCB plating, precious metal plating, automotive parts, and some other higher requirements hardware surface treatment, a pulse rectifier is an ideal solution. Through the pulse output, a more compact, flat, smooth, and pinhole-free surface could be achieved in a shorter time. Less material is required.

The PCB could be deeper and more precisely plated because of the rectifier’s high precision, low ripple factor, real full-bridge soft switch technology which reduces the loss of IGBT.

Also new MOSFET rectify technology is adopted to reduce the circuit voltage 0.1-0.2V, which enhanced the rectifier’s efficiency greatly.

Customization is as requested on your specific crafts requirement.

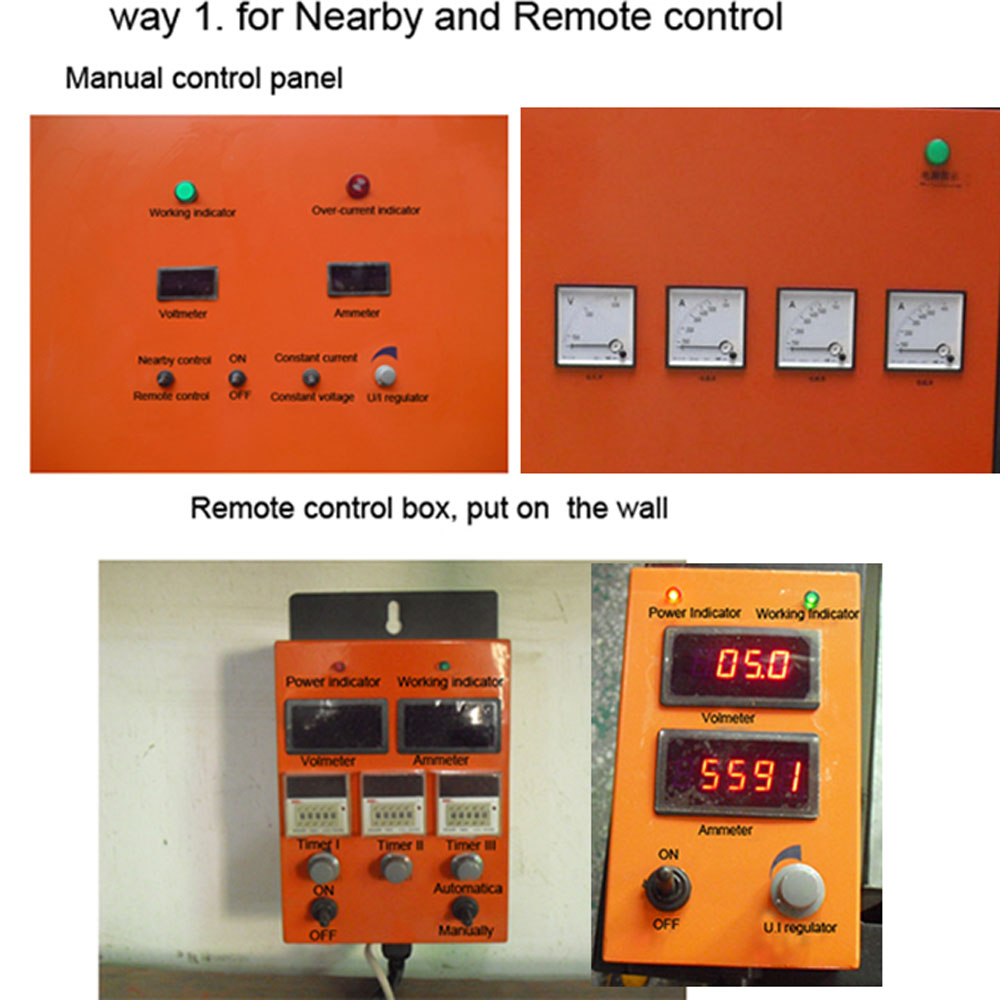

For manual control, it is very convenient to operate locally through the rectifier’s cabinet’s panel, and also an 8-meter cable is provided to connect a remote control box for remote control.

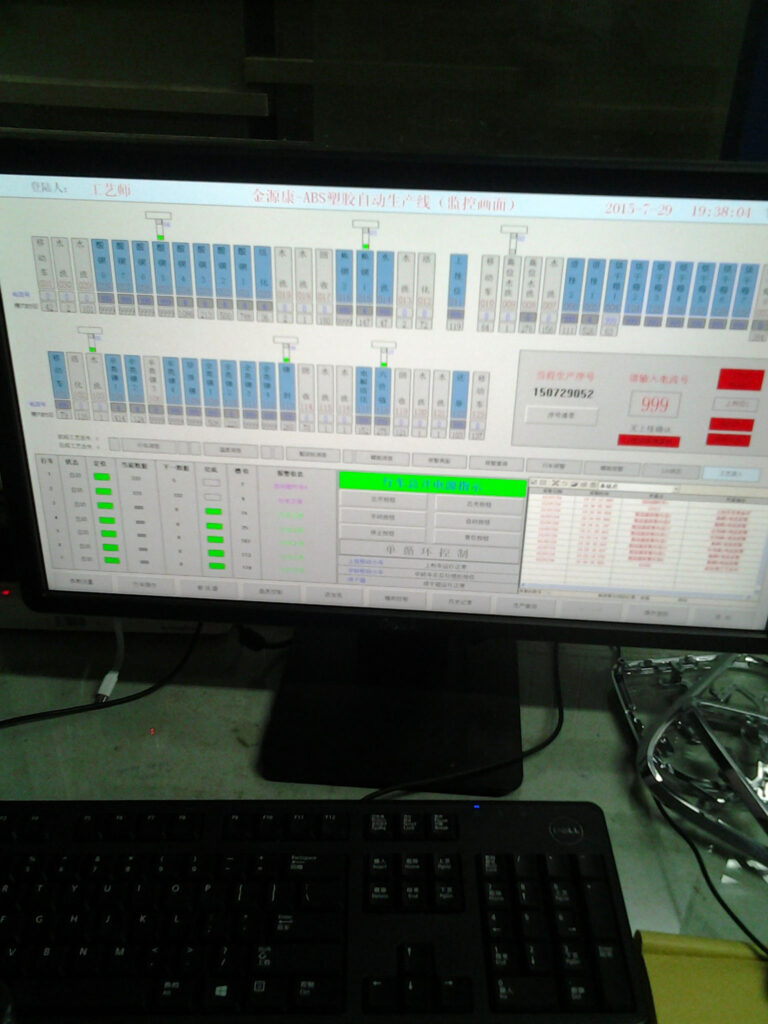

For automatic control, every working process, current process, working currentvoltagetime.etc. data, history data, potential fault indicator, numeral every rectifier to indicate and record its performance. Thus, it can make rectifiers working automatically to avoid human mistakes and help to monitor the working processes to improve plating quality.

Aluminum Anodizing & Coloring

DC output rectifier is widely applied for aluminum anodizing. AC or DC/AC output rectifier is required for the coloring process.

DC output rectifier is widely applied for aluminum anodizing. AC or DC/AC output rectifier is required for the coloring process.

Cabinet modular structure makes the process continues without interruption 7 days one week. Every cabinet is an independently controlled rectifier. It can be connected or wrapped off easily without stopping the rectifier through screws.

Life tests with exact full loading are done at our factory before being packed to maximumly eliminate any potential problems during your installation.

Air cooling or water-cooled IGBT rectifiers, and air cooling, water-cooled, water- oil cooling, and oil cooling thyristor rectifiers are available.

Customization is as requested on your specific crafts requirement.

Monocrystalline & multi-crystalline furnace heating

Multiple output rectifiers could be applied for various applications. When the process needs multiple outputs, even every output is in different voltage and current.

In some case, only bottom furnace need heating supplied by our DC rectifier.

In other cases, both top and bottom furnaces need heating supplied by our DC rectifier. Thus, there are main and auxiliary circuits and outputs are developed. The applications have been tested mature and very reliable.

Actually, all applications need multiple outputs, and every output in different output voltage and current could be customized by our factory.

Electrolytic for Cooper Foil ,Gas Prodution, Stainless Steel Surface Zinc Plating

Our rectifiers could be applied for copper foil, hydrogenchroline special gas electrolytic, color stainless steel surface zinc plating, machinery hard chrome plating, chemical waste electrolytic recycle, and electricity charger industry, etc.

Cabinet modular structure makes the process continues without interruption 7 days one week. Every cabinet is an independently controlled rectifier. It can be connected or wrapped off easily without stopping the rectifier through screws.

Life tests with exact full loading are done at our factory before being packed to maximumly eliminate any potential problems during your installation.

Air cooling or water-cooled IGBT rectifiers. the water-cooled version is an efficient solution with a cabinet in IP56. And air cooling, water-cooled, water- oil cooling, and oil cooling thyristor rectifiers are available. Thyristor rectifier is an endurable solution, even for the harshest environment.

Customization is as requested on your specific crafts requirement.

![]()

Hard Chrome Application

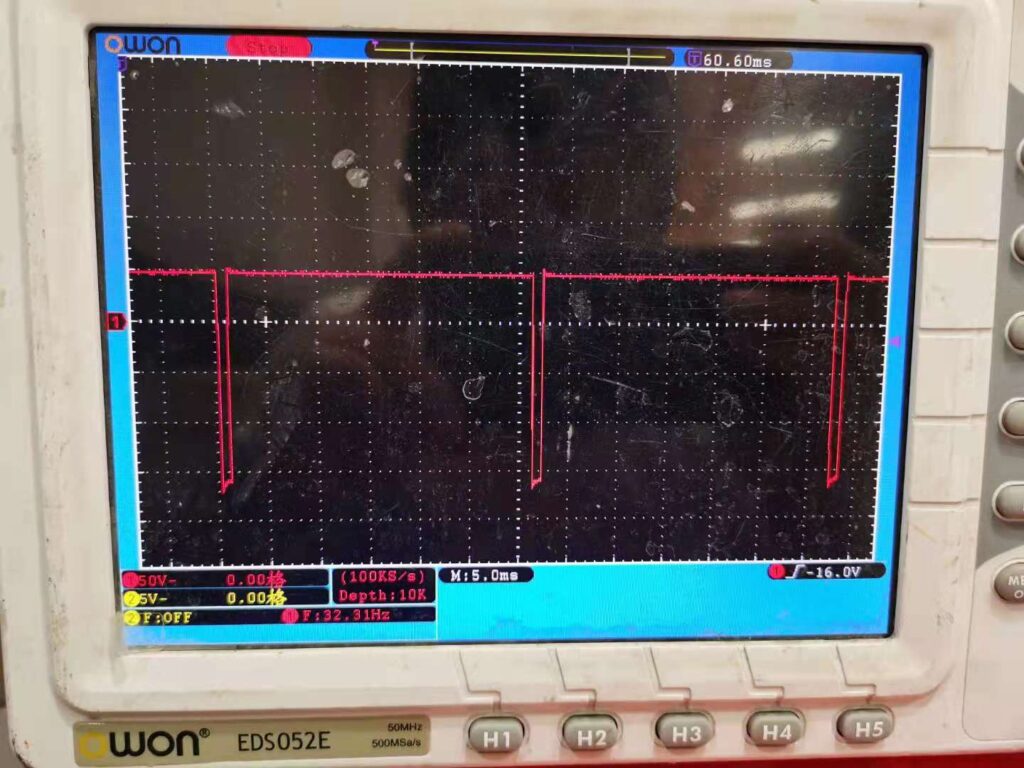

The polarity reverse rectifier is very suitable for hard chrome applications。

The short-time negative output pre-treats metal’s surface. Then the longer positive output supply power for surface hard plating. Thus, a more compact and durable surface could be achieved. The output waveform is similar like this:

Mining Separation Application

Our rectifiers are widely applied for wet and dry mining separation.

Cabinet modular structure makes the process continues without interruption 7 days one week. Every cabinet is an independently controlled rectifier. It can be connected or wrapped off easily without stopping the rectifier through screws.

Life tests with exact full loading are done at our factory before being packed to maximumly eliminate any potential problems during your installation.

Air cooling or water-cooled IGBT rectifiers. the water-cooled version is an efficient solution with a cabinet in IP56. And air cooling, water-cooled, water- oil cooling, and oil cooling thyristor rectifiers are available. Thyristor rectifier is an endurable solution, even for the harshest environment.

Customization is as requested on your specific crafts requirement.